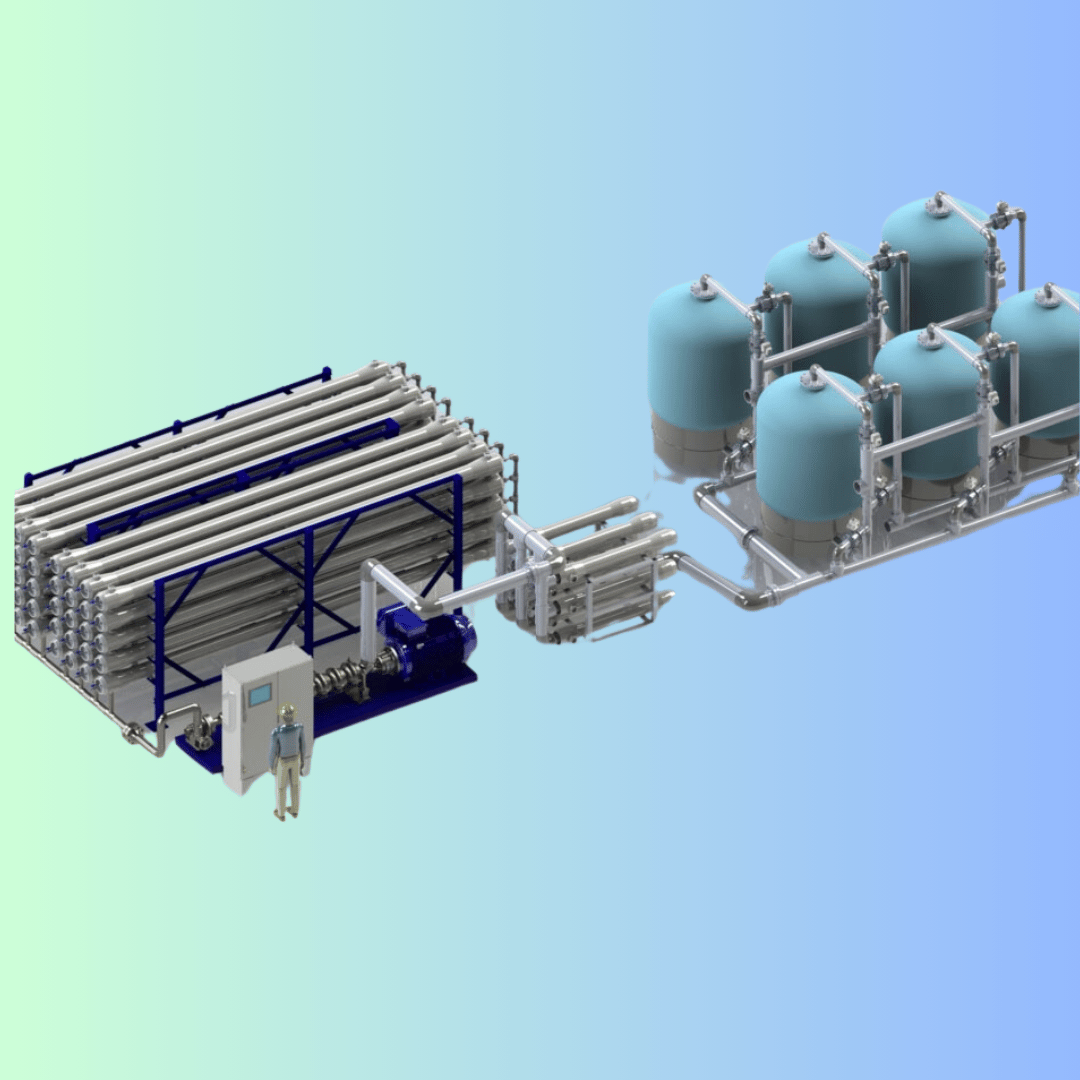

Equipped with energy recovery devices to reduce operational costs and improve efficiency. These systems capture and reuse energy from the pressurized brine stream, significantly reducing energy consumption.

Used for desalinating seawater to produce potable water, commonly found in coastal areas. These systems operate at high pressures to overcome the osmotic pressure of seawater and are built to withstand corrosive marine environments.

Designed to maximize water recovery rates, reducing wastewater and improving efficiency. These systems are optimized to handle higher salinity brackish water while minimizing waste.

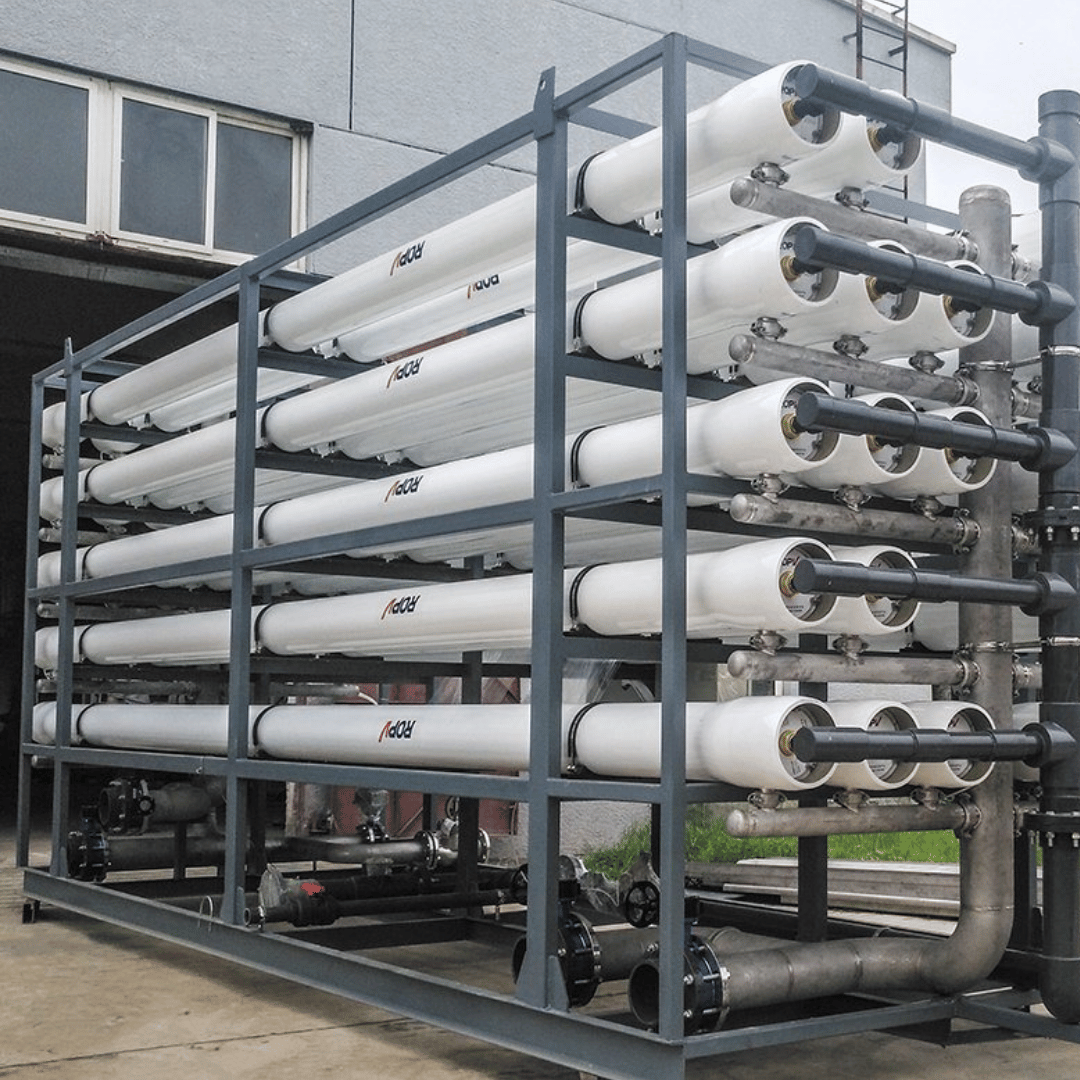

Used to treat brackish water with moderate salinity, these systems are common in inland areas where the water source contains higher levels of dissolved salts. They typically operate at lower pressures than seawater systems.

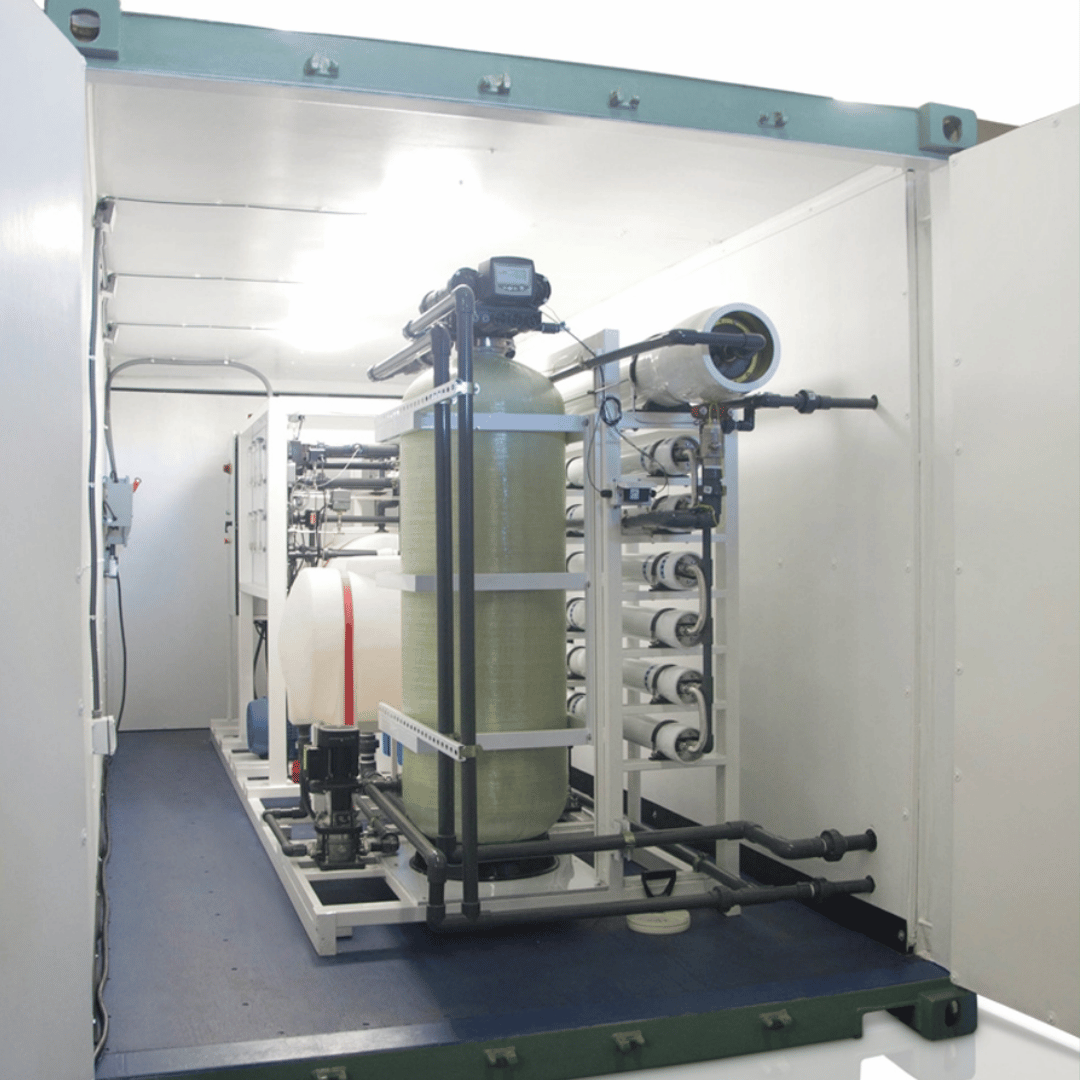

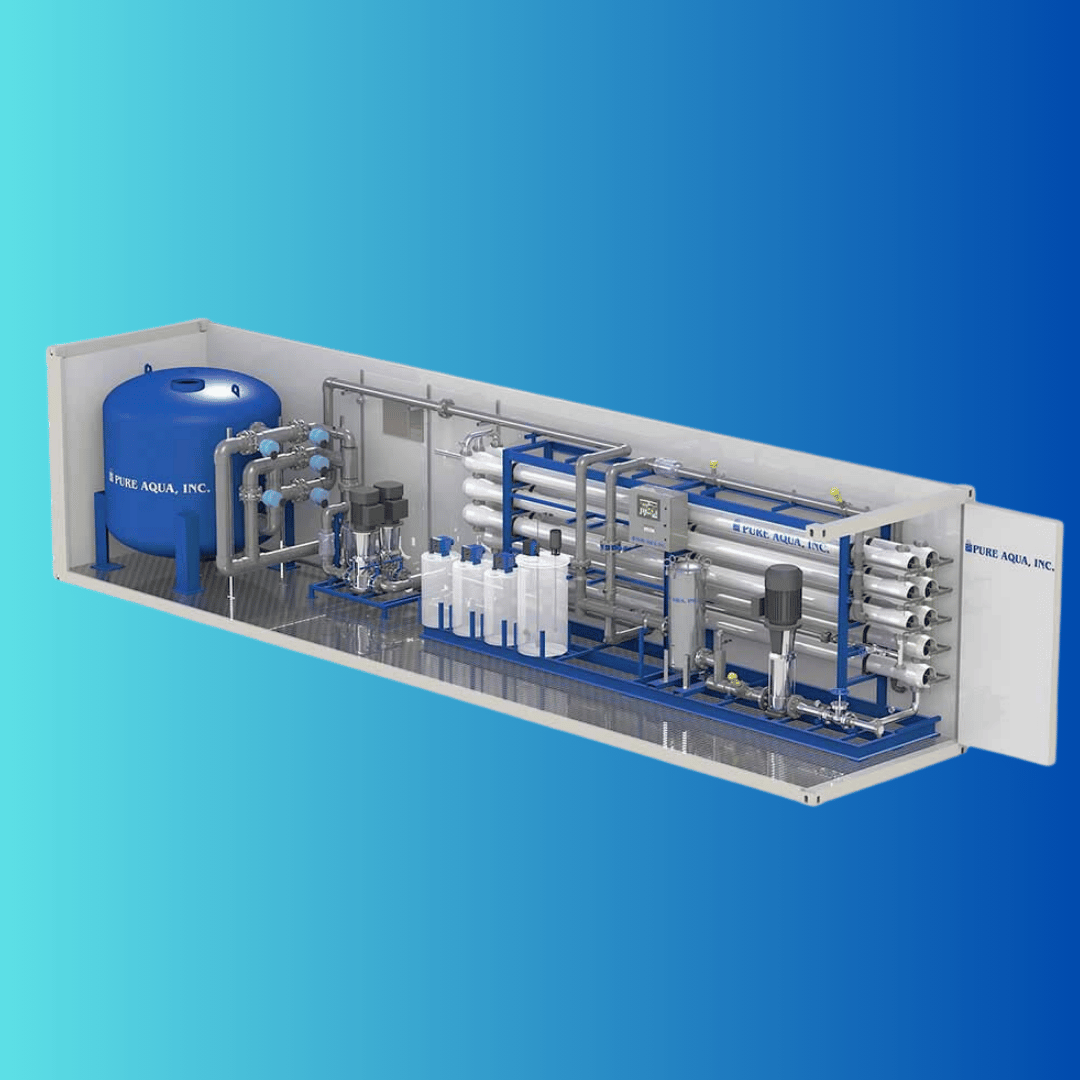

Portable units housed in shipping containers for remote or temporary applications. These systems are pre-assembled and easy to deploy, making them ideal for military operations, disaster relief, and remote industrial sites.

Built for manufacturing plants, power plants, and large-scale water treatment facilities, these systems handle very high volumes of water and remove a wide range of contaminants. They are often customized to meet specific industrial needs.

Suitable for larger businesses, schools, and small industrial applications. These systems can handle higher volumes of water and are often equipped with more advanced features, such as automatic flushing and monitoring systems.

Designed for small businesses, restaurants, and cafes, these systems provide high-quality water for cooking, beverages, and ice machines. They typically have higher capacities than residential systems but are still compact.

Portable units that sit on the countertop and connect to the kitchen faucet. They are easy to install and ideal for renters or small households needing purified water without permanent installation.

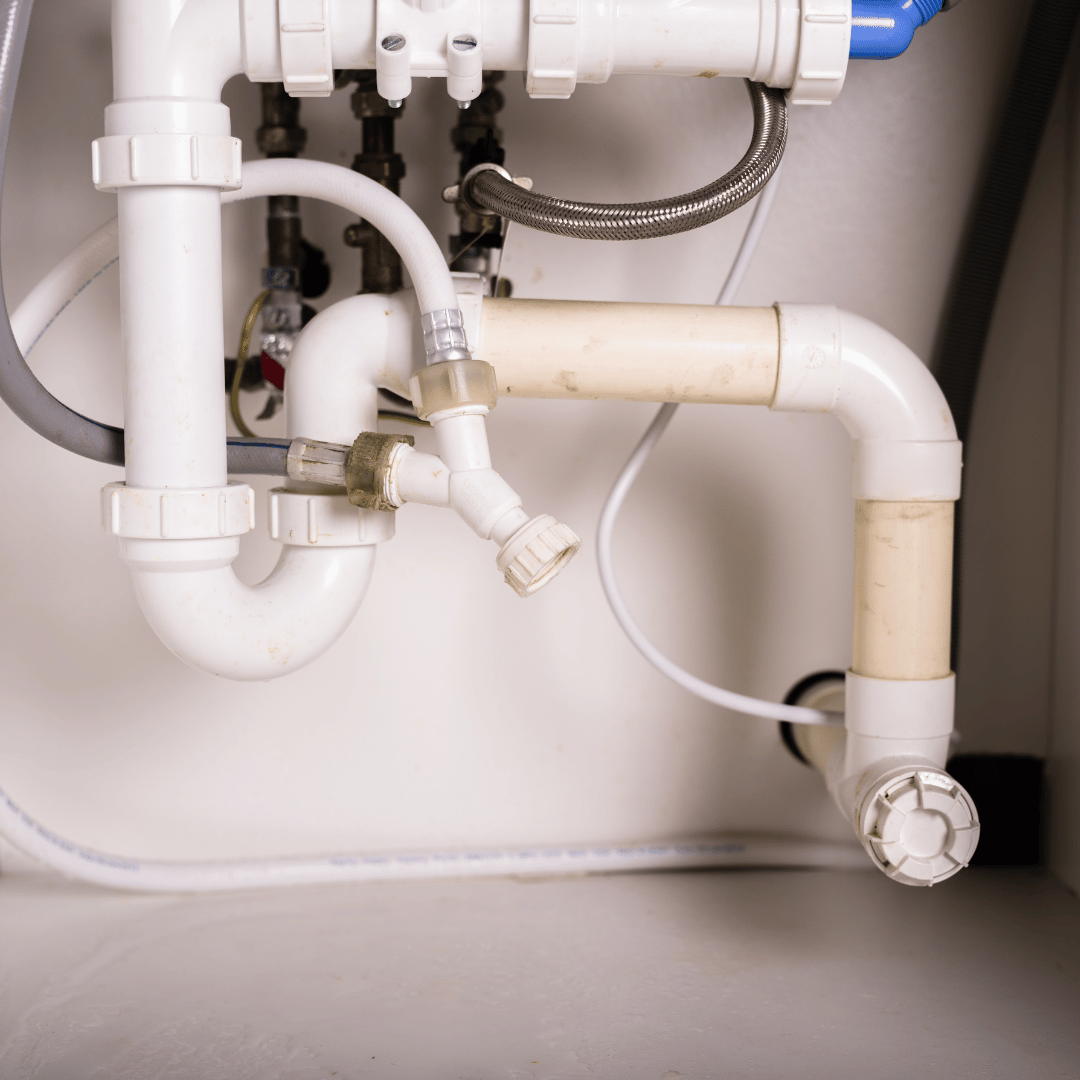

Compact units installed under the kitchen sink to provide purified drinking water. They typically include multiple filtration stages, including sediment and carbon filters, followed by the RO membrane.